5.3 tonne - Hitachi ZX55U-5A Excavator

ZAXIS-5 series Short-tail-swing version

HYDRAULIC EXCAVATOR

Model Code : ZX55U-5A

Engine Rated Power : 28.2 kW (37.8 HP)

Operating Weight : 5 040 - 5 370 kg

Backhoe Bucket ISO Heaped : 0.14 m³

The Hitachi Tracked Excavator is a 5.37 tonne (operating weight) tracked excavator, which we offer on a self-drive or operated basis. For our up-to-date prices please call T:01482 319480. hiredesk@headlandplant.co.uk

The information below is provided by the manufacturer. This may vary depending on the year of the machine.

SPECIFICATIONS

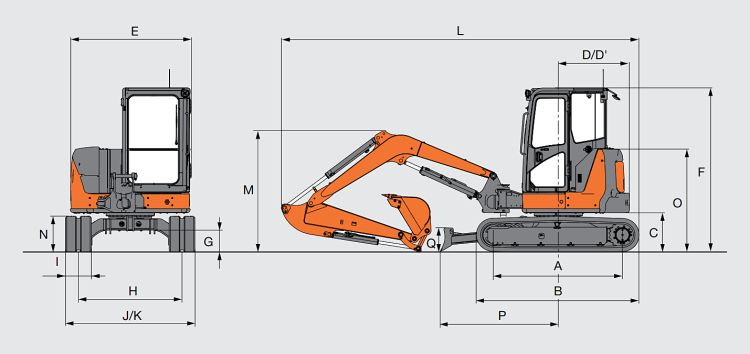

DIMENSIONS

| Unit: mm | ||

| ZAXIS 55U | ||

| A | Distance between tumblers | 2 000 (1 990) |

| B | Undercarriage length | 2 500 (2 490) |

| * C | Counterweight clearance | 610 (590) |

| D | Rear-end swing radius | 1 100 |

| D’ | Rear-end length | 1 100 |

| E | Overall width of upperstructure | 1 850 |

| F | Overall height of cab | 2 530 |

| * G | Min. ground clearance | 340 (320) |

| H | Track gauge | 1 600 |

| I | Track shoe width | 400 |

| J | Undercarriage width | 2 000 |

| K | Overall width (Blade width) | 2 000 |

| L | Overall length | |

| With 1.38 m arm | 5 470 | |

| With 1.69 m arm | 5 520 | |

| * M | Overall height of boom | |

| With 1.38 m arm | 1 710 | |

| With 1.69 m arm | 1 880 | |

| N | Track height | 550 (530) |

| O | Engine cover-height | 1 590 (1 570) |

| P | Horizontal distance to blade | 1 820 |

| Q | Blade height | 375 |

| * Excluding track shoe lug Data in ( ) are dimensions of grouser shoe. |

SPECIFICATIONS

ENGINE

Model ............................. Yanmar EDM-4TNV88

Type ............................... 4-cycle water-cooled, direct injection

No. of cylinders .............. 4

Rated power

ISO 9249, net ................ 28.2 kW (37.8 HP) at 2 400 min-1 (rpm)

EEC 80/1269, net ......... 28.2 kW (37.8 HP) at 2 400 min-1 (rpm)

SAE J1349, net ............. 28.2 kW (37.8 HP) at 2 400 min-1 (rpm)

Maximum torque ............ 139.6 Nm (14.2 kgfm) at 1 100 min-1 (rpm)

Piston displacement ....... 2.189 L

Bore and stroke .............. 88 mm x 90 mm

Battery ........................... 1 × 12 V / 72 Ah

HYDRAULIC SYSTEM

Hydraulic Pumps

Main pump .................... 1 variable displacement axial piston pump

Maximum oil flow ........ 1 x 120 L/min

Pilot pump .................... 1 gear pump

Maximum oil flow ........ 12.0 L/min

Hydraulic Motors

Travel ............................ 2 variable displacement axial piston motors

Swing ............................ 1 axial piston motor

Relief Valve Settings

Implement circuit ........... 24.5 MPa (250 kgf/cm²)

Swing circuit .................. 18.3 MPa (187 kgf/cm²)

Travel circuit .................. 24.5 MPa (250 kgf/cm²)

Pilot circuit .................... 5.9 MPa (60.2 kgf/cm²)

Hydraulic Cylinders

| Quantity | Bore | Rod diameter | Stroke | |

| Boom | 1 | 95 mm | 55 mm | 699 mm |

| Arm | 1 | 80 mm | 50 mm | 731 mm |

| Bucket | 1 | 75 mm | 45 mm | 551 mm |

| Blade | 1 | 105 mm | 50 mm | 140 mm |

| Boom swing | 1 | 90 mm | 50 mm | 666 mm |

UPPERSTRUCTURE

Revolving Frame

D-section frame for resistance to deformation.

Swing Device

Axial piston motor with planetary reduction gear is bathed in oil. Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released disc type.

Swing speed ................ 9.0 min-1 (rpm)

Swing torque ................ 8.6 kNm (877 kgfm)

Operator's Cab

Independent spacious cab, 1 049 mm wide by 1 611 mm high, conforming to ISO* Standards. Reinforced glass windows on 4 sides for visibility. Front windows (upper and lower) can be opened. Reclining seat.

* International Organization for Standarization

UNDERCARRIAGE

Tracks

Tractor-type undercarriage. Welded track frame using selected materials. Side frame welded to track frame.

Numbers of Rollers on Each Side

Upper roller ................... 1

Lower rollers ................. 4

Travel Device

Each track driven by 2-speed axial piston motor. Parking brake is spring-set/hydraulic-released disc type.

Automatic transmission system: High-Low.

Travel speeds ................ High : 0 to 4.2 km/h

Low : 0 to 2.5 km/h

Maximum traction force ... 38.3 kN (3 905 kg)

Gradeability ................... 58% (30 degree) continuous

SOUND LEVEL

Sound level in cab according to ISO 6396 ................................ LpA 75 dB(A)

External sound level according to ISO 6395 and

EU Directive 2000/14/EC ............................................................LwA 96 dB(A)

SERVICE REFILL CAPACITIES

Fuel tank ............................................................................................. 70.0 L

Engine coolant ...................................................................................... 4.7 L

Engine oil .............................................................................................. 8.6 L

Travel device (each side) ...................................................................... 0.9 L

Hydraulic system ................................................................................. 66.0 L

Hydraulic oil tank ................................................................................. 42.0 L

WEIGHTS AND GROUND PRESSURE

Operating Weight and Ground Pressure (CAB model)

| Shoe type | Shoe width | Arm length | kg | kPa(kgf/cm²) |

| Rubber shoe | 400 mm | 1.38 m | 5 170 | 29 (0.30) |

| 1.69 m | 5 200 | 29 (0.30) | ||

| Grouser shoe | 400 mm | 1.38 m | 5 280 | 30 (0.31) |

| 1.69 m | 5 310 | 30 (0.31) | ||

| Pad crawler shoe | 400 mm | 1.38 m | 5 340 | 30 (0.31) |

| 1.69 m | 5 370 | 30 (0.31) |

Including 0.14 m³ (ISO heaped), bucket weight (109 kg).

BUCKET AND ARM DIGGING FORCE

| Arm length | 1.38 m | 1.69 m |

| Bucket digging force ISO | 36.8 kN (3 750 kgf) | 36.9 kN (3 760 kgf) |

|

Bucket digging force SAE : PCSA |

32.1 kN (3 270 kgf) | 32.1 kN (3 270 kgf) |

| Arm crowd force ISO | 24.0 kN (2 450 kgf) | 21.0 kN (2 140 kgf) |

|

Arm crowd force SAE : PCSA |

22.8 kN (2 330 kgf) | 20.1 kN (2 050 kgf) |

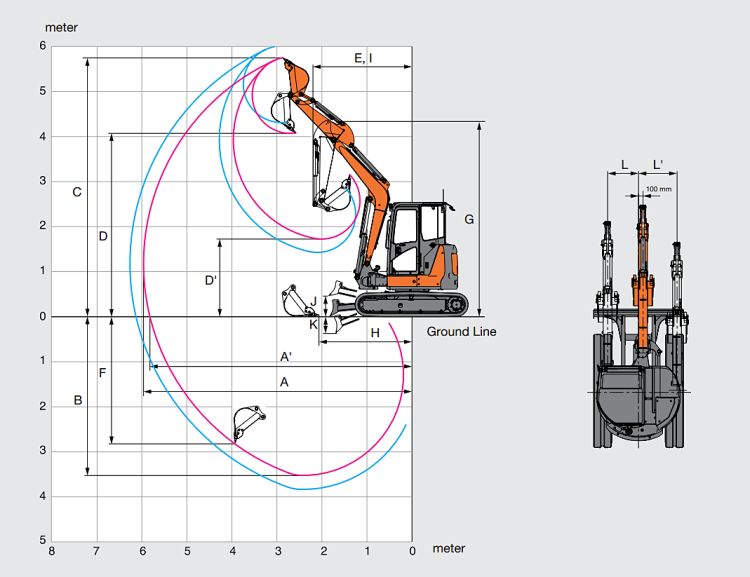

WORKING RANGES

| Unit: mm | |||

| Arm length | 1.38 m | 1.69 m | |

| A | Max. digging reach | 5 960 | 6 260 |

| A’ | Max. digging reach (on ground) | 5 820 | 6 130 |

| B | Max. digging depth | 3 530 | 3 830 |

| C | Max. cutting height | 5 750 | 6 000 |

| D | Max. dumping height | 4 070 | 4 310 |

| D’ | Min. dumping height | 1 720 | 1 430 |

| E | Min. swing radius | 2 210 | 2 300 |

| F | Max. vertical wall digging depth | 2 810 | 3 140 |

| G | Front height at Min. swing radius | 4 380 | 4 380 |

| H | Min. level crowding distance | 2 050 | 1 880 |

| I | Working radius at Min. swing radius (Max. boom-swing angle) | 1 730 | 1 810 |

| J | Blade bottom highest position above ground | 460 | 460 |

| K | Blade bottom lowest position above ground | 365 | 365 |

|

L/L’ |

Offset distance (Max. boom-swing angle) Max. boom-swing angle |

690 / 850 80 / 60 |

690 / 850 80 / 60 |

| Excluding track shoe lug. |

The new Hitachi ZAXIS 55U mini excavator has been designed with one aim in mind – to enable our customers to make their visions a reality. It sets a new standard in terms of performance, comfort and maintenance, and builds upon the Hitachi reputation for versatility, reliability and durability. For owners, it meets the need for efficiency and high quality; for operators, it provides a comfortable, safe working environment and is extremely user-friendly. Thanks to a range of easy maintenance features and with the help of the Hitachi Support Chain after-sales programme, the new ZAXIS 55U delivers excellent levels of availability, allowing you to bring every task to a satisfying conclusion – on time, on budget and to a high standard.

WALK AROUND

Reduced fuel costs

The advanced energy saving system of the new ZAXIS mini excavator has significantly reduced fuel consumption

Improved durability

Strengthened front joints, an improved swing post and boom cylinder guard are among the new features of the ZAXIS mini excavator range.

Greater versatility

With the standard stack muffler, auto shift travelling and a variety of optional parts, the new ZAXIS 55U is suitable for a wide range of applications.

Large cab

The wide operator seat, enhanced armrest and easy access to the cab of the new ZAXIS provide a more comfortable working environment for the operator.

Ultimate comfort

Additional air conditioning vents ensure the cab remains at a comfortable temperature all year round.

Short-tail swing radius

The short-tail swing radius makes the ZAXIS mini excavator ideal for working in confined spaces, particularly in urban areas on road construction and utilities projects.

Easily accessible information

The large multi-function LCD monitor screen provides technical data and is easy to view during the day and at night.

Quick and easy service access

The new ZAXIS has wide covers that are easy to open, and the radiator and oil cooler are conveniently located side by side.

PERFORMANCE

Like all new ZAXIS models, the mini excavator range has been designed to deliver high levels of productivity and reduced running costs. Suitable for working on such projects as earthmoving, utilities and general construction – and particularly where space is limited – they are fast, powerful and fuel-efficient. They are also extremely durable, thanks to several new design features, which have been incorporated by Hitachi to ensure that they provide an outstanding level of performance on any job site.

Designed to reduce running costs and built to last

Lower fuel costs

To stand out in today’s competitive construction market, your choice of machinery is vital. The productivity and efficiency of your equipment has a direct impact on your company’s profitability and ultimately its success. These considerations were at the heart of the development of the new range of ZAXIS mini excavators.

For example, an advanced energy-saving system has been incorporated into the new ZAXIS 55U model. It combines the ECO mode, auto idle and isochronous control features of the excavator to significantly reduce fuel consumption. Further benefits of this system include lower noise levels and emissions.

Fuel efficiency is also assured by the ZAXIS mini excavator’s all-new engine, which is paired with an electronic governor. Working with the efficient HHH hydraulic system, it ensures that the excavator works with less fuel than the previous ZAXIS model (3% less in PWR mode*), while maintaining high levels of productivity.

Greater durability

Working on a variety of construction projects under the pressure of deadlines requires reliable and durable machines that help you to get the job done on time and within budget. The new ZAXIS mini excavators are extremely durable, thanks to a range of new and improved features.

The front joints of the machine have been strengthened, the swing post has been improved and the D-frame has also been reinforced. The ZAXIS 55U is also equipped with a boom cylinder guard and a box sectioned rigid frame blade. A shorter pilot shut-off lever also provides added durability.

The overall performance of your equipment depends on high levels of availability and productivity. We believe that you will be able to enjoy a lower cost of ownership thanks to the durability of our new ZAXIS mini excavators.

* Based on the measurement with the Hitachi test rule

Key features

* Auto shift travelling system

* Accumulator (optional)

* HHH hydraulic system

* Auto idle system

* ECO mode

* Boom cylinder guard

* Box sectioned rigid frame blade

COMFORT

The new ZAXIS mini excavator may look compact on the outside, but the spacious cab proves that it is big on the inside.

Hitachi design engineers consulted the views of operators all around the world on the most important considerations for the interior of the machine. As a result, they have developed a comfortable working environment with enhanced visibility, user-friendly features and a greater sense of space than the previous Hitachi models. It helps the ZAXIS 55U to set a new standard on any job site.

The cab of the new ZAXIS mini excavator is bigger and better

From the comfort of the cab

If you’re spending the majority of your working day in the cab of a Hitachi ZAXIS mini excavator, it’s important that you feel comfortable and at ease while you work. Hitachi has designed the new ZAXIS 55U with the operator firmly in mind, so that you will feel less tired at the end of your day on the construction site.

The wide seat and large cab interior are two of the most obvious changes to the new mini excavator range. There is more leg room thanks to the folding foot pedals, and an adjustable armrest also allows the operator to find the most comfortable seated position. Access to and from the cab is also easier thanks to the introduction of an entrance step.

Enhanced visibility

An enlarged front window and door also contribute to the greater sense of space compared to the previous models, while also providing greater visibility. This is particularly important on busy construction sites and when working in compact spaces, to avoid unnecessary damage to the machine, or health and safety issues for the operator.

At your fingertips

The power lies firmly in the hands of the operator in the new ZAXIS mini excavator, as Hitachi has incorporated a number of user-friendly features.

The new multi-function LCD monitor has a large three-and-a-half inch screen that is easy to view in bright sunlight or at night. It provides all vital technical data at a glance, including the machine’s status and settings, and is positioned within easy reach of your right hand. The proportional switch in the new, optional, auxiliary function lever allows easy control of the front attachment.

Enjoy your day

We wanted to ensure that our operators would be happy with the changes to the interior of the new ZAXIS mini excavator range, because we realise that a happy operator is also a more productive one. The emphasis of many of the new developments was on creating a pleasant working environment.

Additional air conditioning vents have been introduced to the rear of the cab, for example, to ensure that the climate within it remains comfortable, whatever the weather. The pressure of the ROPS cab has also been increased for the new ZAXIS model to reduce the amount of dust entering the cab.

Key features

* Enhanced visibility

* New LCD monitor

* Easily accessible information

* Expansive leg room

* Wide and comfortable seat

* Folding foot pedals and adjustable armrest

* Improved air conditioning

* Auxiliary function lever (optional)

MAINTENANCE

The new ZAXIS mini excavators will deliver high levels of availability, wherever in the world they are required to work.

This is thanks, in part, to the Hitachi reputation for manufacturing reliable and durable machines. It is also due to their range

of convenient maintenance features, which allow you to carry out quick and easy cleaning and service tasks on the job site.

So, you can be assured of their optimum performance at all times.

Enjoy trouble-free days on the jobsite thanks to easy maintenance

Easy acces

The new range of ZAXIS mini excavators has been designed with a variety of convenient features with the aim of making routine maintenance and servicing quick and easy for our customers.

The excavator’s daily inspection points have been grouped together to allow for quick access, so that you can continue with your work as soon as possible. The cooling pack has also been arranged in parallel to achieve greater cooling efficiency.

The covers of the ZAXIS 55U excavator, including those for the radiator, engine and fuel tank, have been designed to open widely and conveniently. A tilting device for the tilt-up floor is available as an option, providing even greater access for service and maintenance procedures.

Information on the new ZAXIS mini excavator is also easy to access, thanks to the Global e-Service and Owner’s websites (available as an option). This enables you to access operational data on each machine online, helping you to plan preventative maintenance and manage your fleet remotely.

Easy cleaning

A clean machine ensures optimum performance and helps to minimise downtime. Hitachi has introduced several new features to the new ZAXIS mini excavator range to help you keep it in excellent working order and maximise its availability. Inside the cab, the new two-piece floor mat can be removed and cleaned easily. An interior filter has been fitted to the air conditioning system, so that dust and

air particles can be captured effectively.

Support Chain

To further protect your investment in your new ZAXIS mini excavator, the Hitachi Support Chain after-sales programme gives you the flexibility to create a tailor-made service plan. This can include: Global e-Service, technical support, extended warranty and service contracts, and parts and remanufactured components. Each one of these is a link in the chain of service available from Hitachi via your local dealer. For more details, please contact your local dealer.

Key features

* Spacious tool box

* Improved grease points

* Easy to open covers

* Global e-Service (optional)

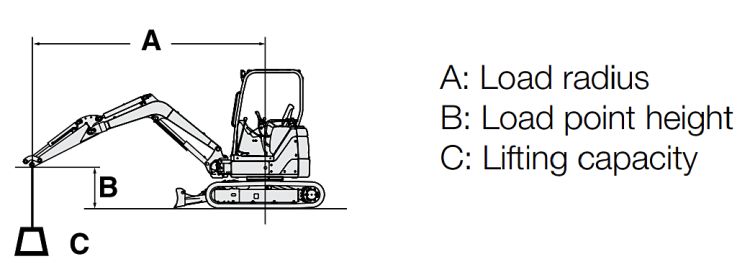

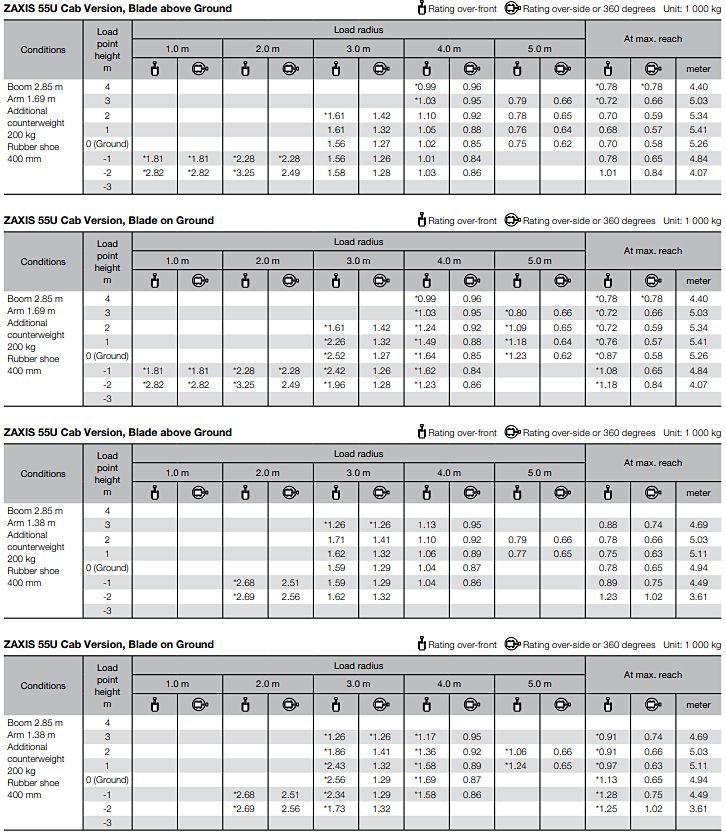

LIFTING CAPACITIES

Notes: 1. Ratings are based on ISO 10567.

2. Lifting capacity does not exceed 75% of tipping load with the machine on firm, level ground or 87% full hydraulic capacity.

3. The load point is the center-line of the bucket pivot mounting pin on the arm.

4. *Indicates load limited by hydraulic capacity.

5. 0 m = Ground.

For lifting capacities, subtract bucket and quick hitch weight from lifting capacities without bucket.